Description du projet

high-speed double-layer mixer

détails du produit:

| Lieu d'origine: | Zhengzhou,Chine |

|---|---|

| Marque: | SINCOLA |

| Attestation: | OIN,CE,GV |

| Numéro de modèle: | SLJ |

Paiement & Conditions d'expédition:

| Quantité minimum d'achat: | 1ensembles |

|---|---|

| Prix: | USD960-1200 |

| Détails de l'' emballage: | Forfait Nude dans un conteneur de 20 pieds |

| Délai de livraison: | 2jours |

| Modalités de paiement: | L/C, D/A, D/P, T/T, Western union, MoneyGram |

| Capacité d'approvisionnement: | 1sets 2day |

| Modèle | SLJ-300-580/SLJ-300-700 | Sortir: | 300 L/min -500L/min |

|---|---|---|---|

| Mixing volume: | 300L | Storage volume: | 750L |

| Rated speed: | 50tr/min | Agitator speed: | 33tr/min |

| Motor Power: | 4/1.5kW | Electricity Phase: | Single/Three |

LISTE DE PRODUITS

| Modèle | SLJ-500 | SLJ300-580 | SLJ300-750 |

| Rated speed | 50tr/min | 50tr/min | 50tr/min |

| Agitator speed | 50tr/min | 33tr/min | 33tr/min |

| Mixing volume | 500L | 300L | 300L |

| Storage volume | 500L | 580L | 750L |

| Motor Power | 3kW | 4/1.5kW | 4/1.5kW |

double cement mixer

double cement mixer

double cement mixer

double cement mixer

double cement mixer

double cement mixer

double cement mixer

double cement mixer

double cement mixer

double cement mixer

double cement mixer

double cement mixer

Mixer use material specifications:

- The ash, sand and other materials contained in the mixer shall have a maximum particle size of not more than 5 mm and shall not be mixed with stones and other sundries (such as nails, vegetation, etc.).

2, mixer slurry ratio: according to the mortar pump slurry requirements material selection and configuration.

The consistency of the slurry stirred by the mixer is in accordance with the requirements of the mortar pump.

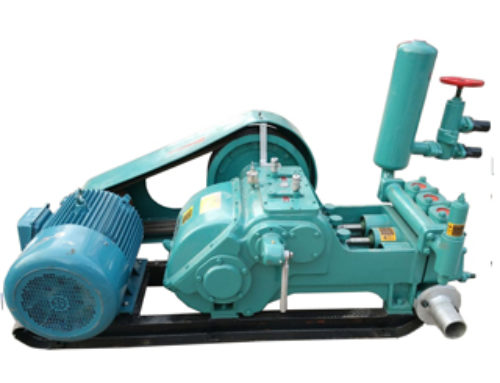

- This machine can continuously mix cement mortar and mortar, which is the best supporting equipment for grouting pump. Sub-motor, horizontal reducer, mixing drum, storage bucket four parts.

- Used for mortar mixing, it can be used with piston grouting pump, bw150 grouting machine, bw160 grouting machine, bw250 grouting machine and other grouting pumps.

- It can be used in construction and maintenance of construction metallurgy, railway bridges, prestressing, etc.

- The mixer is small in size, light in weight, easy to install and carry, and easy to operate and use.

- cement mixer have double-deck chambers, including the upper chamber for slurry mixing and the lower chamber for slurry storage.

- Reasonable structure, high efficiency and simple operation.

- High production efficiency, well material mixing uniformity, small size, light weight, flexible movement, easy maintenance and cleaning.

- Superior abrasion resistance parts. Mixer blades are made of die stamping, no distortion, high strength.